Thermal IR Security Cameras for Zero-Light Surveillance: Use-Cases, Tuning, False-Alarm Control & Buyer’s Guide

By Justin C., Video Security System Specialist — A2Z Security Cameras

Last updated: September 4, 2025

Thermal IR security cameras deliver reliable detection in zero light. They also perform in fog, smoke, glare, and harsh backlighting without adding lighting. For fence lines, shorelines, critical perimeters, mobile platforms, and industrial sites, thermal imaging lets you detect and then trigger visible/PTZ call-ups to identify. Drawing on nearly 20 years of field deployments, this guide shows where thermal excels and where it doesn’t, how to tune images/analytics and control false alarms, key pricing drivers (uncooled vs cooled, resolution/pixel pitch, optics, frame-rate/export class), and high-level export basics.

We also cover how A2Z solutions support security and broader uses—from license plate recognition (via PTZ/visible call-up) to industrial inspection, conservation, and search & rescue—on mobile/portable and on-grid systems, plus edge-first designs for solar/off-grid deployments.

Executive Summary (TL;DR)

- Thermal surveillance cameras detect in zero light and through haze/glare; pair with visible/PTZ for identification (faces/plates).

- Cost drivers: sensor family (uncooled LWIR vs cooled MWIR/LWIR), resolution/pixel pitch, germanium optics, and frame rate/export class.

- False-Alarm Control: object-based analytics, ROI weighting, stable AGC/DDE, and dual-tech (radar/PIR) at high-consequence sites.

- Where it shines: long approaches, privacy-sensitive zones, waterfront/fog corridors, remote gates, mobile masts/UAVs.

- Off-grid: predictable power (no illuminators), edge-first storage; send thumbnails/clips over LTE/LEO/PTP and bulk-sync off-peak.

- Compliance: mainstream ≤9 Hz uncooled LWIR is broadly available; higher-performance classes may be export-controlled.

Who this is for

- Security managers: quick orientation, strengths/limits, budget drivers.

- Integrators/designers: deployment patterns, tuning, analytics, and VMS/ONVIF workflows.

- Engineers/advanced: deep dives (Johnson’s, NETD, AGC/DDE/ROI), buyer details, glossary.

1) Quick Orientation (for decision-makers)

What “Thermal IR” Means (and What It Doesn’t)

Thermal infrared (Thermal IR) cameras detect long-wave infrared radiation (heat patterns), not reflected visible light. They do not need IR or white lighting and are not the same as IR-illuminated visible cameras.

Also in the market: multi/dual-spectrum devices combine thermal + visible in one housing or coordinated pair (detect on thermal; verify/ID on visible).

Thermal families you’ll actually deploy - Mixed-modality bullets/turrets: one housing with visible + thermal aligned (thermal detection → visible confirmation).

- Thermal-only fixed lenses: various FOVs; common for fence lines, open areas, shorelines, equipment corridors.

- Thermal + PTZ combos: thermal provides wide-area detection; a linked PTZ slews to a preset for identification (faces/plates/vehicle attributes).

Temperature-measuring variants: Many commercial thermals include temperature measurement/alarms. A2Z supports both detection-focused and temperature-capable variants.

Where Thermal Excels

- Zero-light surveillance: critical facilities, remote gates, conservation areas where lighting is undesirable.

- Fog/smoke/backlight corridors: waterfronts, industrial approaches, sun-glare roads.

- Privacy-sensitive zones: silhouettes and motion (easier stakeholder approvals).

- Large open approaches: cover more ground with fewer cameras than visible-only designs.

- Mobile/portable: vehicle masts, solar skids, UAV/UGV payloads for wide-area sweeps.

For identification (license plates, faces, brands), thermal is paired with visible or PTZ call-ups: detect → confirm.

When Thermal Is Not the Primary Tool

- Identification-first needs: plates/faces/color → visible/IR + PTZ.

- Targets behind glass: LWIR doesn’t pass common glass; visible or SWIR may be required.

- Tight indoor scenes: short range + fine detail usually favors visible.

- Complex hot backgrounds: flare stacks/HVAC plumes reduce contrast; mitigate with masking, angles, or mixed modality.

- Export limits: high-performance cooled/high-FPS thermals may be restricted.

Thermal vs IR-Illuminated Visible vs Mixed-Modality (Quick Compare)

| Factor | Thermal (LWIR) | IR-Illuminated Visible | Mixed-Modality (Thermal + Visible) |

|---|---|---|---|

| Light required | No | Needs IR/white light | Thermal: no; Visible: event lighting |

| Strength | Reliable detection in zero light/fog | Identification (faces/plates) with lighting | Detect on thermal, confirm on visible |

| False alarms | ROI + analytics | Glare, insects, blooming | Lower with dual-confirm |

| Power impact | Modest/steady | Higher (illumination) | Moderate; event-based visible/PTZ |

| Typical use | Fence lines, long approaches | Gates, ID-critical | Critical sites needing both |

Detection vs Recognition vs Identification (Field Expectations)

From Johnson’s criteria (pixels on target + contrast): - Detection: “something is there.”

- Recognition: “human vs animal; vehicle type.”

- Identification: “this specific person/plate” → typically visible/PTZ.

Planner tip: pick resolution + focal length for detection/recognition; drive PTZ presets for ID.

2) Planner’s Toolkit (for integrators & designers)

Cost & Market Realities (Why Thermal Costs More)

- Sensor family: Uncooled LWIR microbolometers are mainstream; cooled MWIR/LWIR add cryogenics → big cost.

- Resolution & pixel pitch: 320×240 and 640×512 common; smaller pitch (e.g., 12 μm) can improve detail; cost rises with clarity.

- Optics: Germanium lenses; longer focal lengths and motorized zoom increase price.

- Frame rate: higher FPS drives cost and may be export-controlled; ≤9 Hz is widely available commercially.

- Environmental build: heaters/defog, rugged housings, precise calibration.

- Analytics & integration: object-based analytics, dual-sensor sync, PTZ/VMS integrations (often licensed).

Trend: costs are improving as adoption grows; more general security and industrial projects now benefit from thermal.

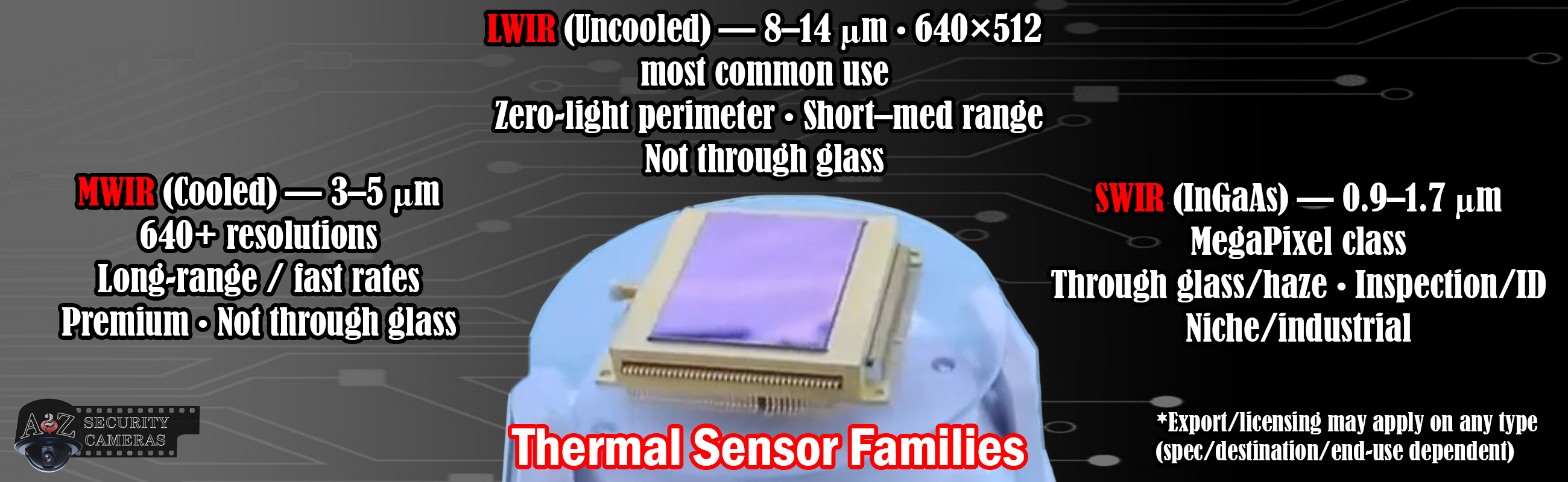

Sensor Families & Resolution (Quick Orientation)

| Family | Typical band | Cooling | Security-grade resolutions | Common frame rates | Where it shows up |

|---|---|---|---|---|---|

| LWIR microbolometer (uncooled) | 8–14 μm | Uncooled | 320×240, 640×512 | ≤9 Hz widely available | Perimeter/area detection, zero-light surveillance, mixed-modality bullets |

| MWIR (cooled) | ~3–5 μm | Cooled (cryogenic) | 640×512 and above | Higher rates common | Long-range/specialty defense & industrial (costly) |

| SWIR (InGaAs) | ~0.9–1.7 μm | Often cooled | Megapixel-class | Higher rates | Imaging through haze/glass/materials; niche security/industrial |

Planning cue: For most surveillance, uncooled LWIR 320×240 or 640×512 is the sweet spot. Choose focal length + resolution to hit detection/recognition ranges; automate PTZ call-ups for ID.

Regulatory/Export Basics (High-Level, Non-Legal)

Some thermals fall under U.S. export controls (ITAR or EAR). Many commercial uncooled LWIR models (≤9 Hz, 320×240 or 640×512) are widely available. Higher-performance (cooled/high-FPS/high-res) may require licensing and be limited to eligible users/geographies.

Disclaimer: This is general info, not legal advice. A2Z can help route you to the right product class and documentation.

Deployment Patterns That Work (With Why)

- Fence-line sweeps: fixed-lens thermal every 100–300 m (terrain/FOV). Tripwires along the line; PTZ call-ups at gates/corners. Why: minimal cameras, consistent tripwire.

- Waterfront / open field: wider lens; ROI at waterline/shore; higher mounts to minimize sky. Why: reduce AGC pumping and false alarms.

- Remote gate / road approach: mixed-modality bullet (thermal+visible) down-road; PTZ preset at stop-bar for plates/faces. Why: instant verify + evidence.

- Substation / plants: corner thermal to avoid internal hot clutter; visible + analytics inside for assets. Why: limit hot-zone false triggers.

- Mobile/portable: vehicle mast or solar skid with thermal sweep; PTZ confirms; edge-first storage; LTE thumbnails/clip sync. Why: rapid deploy, low power.

Related deep dive: Panoramic & Multi-Sensor vs PTZ (Solar Sites).

Solar/Off-Grid Notes (Why Thermal Often Fits)

Thermal’s steady draw is modest versus visible solutions requiring illuminators, and bitrate is typically lower. Pair thermal with edge recording/analytics and event-based PTZ call-ups, keeping power predictable. See Solar Camera Power Planning Guide for winter PSH and recovery sizing.

- Backhaul: thumbnails + short clips on events; bulk sync overnight or via PTP when available.

- Resilience: watchdog reboots, scheduled NUC, health pings, storage margin for multi-day storms.

Integration: Turning Detection into Evidence

- ONVIF/VMS events: thermal trip → PTZ preset, visible snapshot/clip, bookmark/tag with metadata.

- Edge-first + selective sync: local record; send thumbnails/event clips to VMS/cloud; bulk pulls during off-peak.

- Deterrence options: on verified events, trigger white light or audio within duty schedules and power budget.

- Health monitoring: temperature window/NUC alerts; analytics heartbeat to validate uptime.

Quick Focal Length + Resolution Table (Rule of Thumb)

(Exact ranges vary by model, pixel pitch, scene, and analytics. Validate on site.)

| Use-case | Typical focal length | Typical resolution | Why |

|---|---|---|---|

| 100–150 m fence spans | 13–19 mm | 320×240 or 640×512 | Broad FOV; solid human/vehicle detection |

| 150–300 m fence spans | 25–35 mm | 640×512 preferred | Narrower FOV; longer-reach detection/recognition |

| Long approach (300 m+) | 35–50+ mm | 640×512 (or higher-spec) | Long standoff; pair with PTZ for ID |

| Gate/road short standoff | 7–13 mm | 320×240 workable; 640×512 sharper | Wide view, fast confirm; often mixed-modality |

3) Deep Dive (for engineers & specialists)

Commissioning & Tuning (Practical Playbook)

Goal: stable contrast on the zone that matters, minimal pumping, clean PTZ handoff.

- Polarity: Start White Hot for silhouettes; try Black Hot for bright backgrounds (water/sky) to avoid inverted glare.

- AGC (Auto Gain Control): prefer stable or “outdoor” profiles; avoid rapid gain swings that chase sky/clouds/waves. If available, set moderate gain compression to prevent blooming.

- DDE (Digital Detail Enhancement): start low; increase until edges pop without halos. Over-sharpening creates false edges for analytics.

- ROI weighting: put ROI boxes exactly on fence line/waterline or corridor; exclude sky and hot exhaust stacks.

- NUC (Non-Uniformity Correction): schedule flat-field calibrations for low-risk times; avoid frequent shutters during busy hours. If shutterless, monitor stability and run manual NUC after large ambient changes.

- Focus & boresight: focus at operating temperature; recheck after sunset when temperature deltas are largest. Align thermal FOV with PTZ/visible capture zone so call-ups land correctly.

- Mounting: elevate to reduce horizon clutter; avoid HVAC/exhaust plumes; consider wind load and vibration (use stiff mounts, guying if needed).

- Analytics handoff: map thermal alarm → PTZ preset; verify preset return-to-home and dwell; test both day and night.

Plain-English tip: tell the camera what part of the image matters (ROI), keep its contrast steady (AGC), add just enough “edge pop” (DDE), and make sure your PTZ lands where the thermal trips.

False-Alarm Control (Root Causes & Fixes)

| Driver | Why it fires | What to do |

|---|---|---|

| Small animals/birds | Warm, fast movers at close range | Size/speed filters; direction rules (e.g., “crossing fence line”); ignore lower near-field |

| Waving vegetation | Repeating edges + temp micro-shifts | Prune/clear lanes; mask hot spots; bias ROI away from tops of bushes |

| Water reflections/sun glint | Dynamic contrast on waves/sparkle | ROI above waterline; try Black Hot; compress AGC; raise mounting height |

| Hot machinery/exhaust | Static hot zones appear as “objects” | Hard-mask static hot areas; require dwell/time-in-zone |

| Rain/fog bursts | Contrast collapses; AGC pumps | Stable AGC profile; conservative DDE; radar/PIR confirm on critical segments |

| Insects on lens | Large hot blur blocking FOV | Mild ring heater; insect deterrent gel/rings; regular lens cleaning cadence |

Best practice: favor object-based AI analytics over raw motion. Add radar or PIR on high-consequence segments for dual-tech confirmation.

Expanded Comparisons & Topologies

Thermal vs Radar vs PIR (and when to combine)

| Tech | Strengths | Weaknesses | Best Fit |

|---|---|---|---|

| Thermal | Visualizes heat; wide-area detection; privacy-friendly | Hot clutter can confuse; ID requires visible/PTZ | Open approaches, waterfronts, privacy-sensitive zones |

| Radar | Range/velocity; all-weather; no lighting needed | No visuals; multipath/reflections near metal | Long straight corridors, high wind/rain sites |

| PIR | Very low power; simple | Narrow FOV; heat-source false alarms | Small zones, battery nodes, confirm triggers |

Combine: Thermal + Radar (or PIR) → Radar validates motion physics; thermal provides visual evidence and PTZ trigger.

Thermal vs White-Light at Night

| Factor | Thermal | White-Light Visible |

|---|---|---|

| Power | Modest (no floodlights) | Higher (continuous/triggered) |

| Nuisance | Low (no light pollution) | Can disturb neighbors/wildlife |

| Fog/glare | Thermal wins | Risk of bloom/glare |

| ID (faces/plates) | Needs PTZ/visible | Yes (with proper exposure) |

Mixed-Modality Topologies

- Single-housing dual-sensor (thermal+visible): compact, aligned views, simplified install; may limit lens independence.

- Twin-device orchestration (separate thermal + PTZ): flexible optics and angles, stronger ID; more cabling and integration work.

- Thermal + overview fixed + PTZ: overview context always recording; PTZ only moves on verified thermal.

Field-Style Vignettes (Outcomes & Lessons)

- Oil & gas manifold corridor: uncooled 640×512 thermals down a pipe alley; ROI masks on flare stacks; object analytics cut nuisance alarms by ~70%. On verified alarms, PTZ captures color ID; clips sync to VMS overnight via PTP.

- Windy power substation: corner-mounted thermals with masked transformer zones; wind-rated mounts; scheduled NUC stabilizes uptime. PTZ presets confirm vehicles/persons at gates; alarm rates normalize after excluding steady hot equipment.

- Port & waterfront: wide-FOV thermal covers docks with ROI at waterline; mixed-modality bullets at ramps for visible confirmation. Clips trickle over LTE; weekly bulk pulls via on-site PTP.

- Pipeline road approach (remote): mixed-modality unit monitors approach; directional rules filter wildlife; compact PTZ locks to stop-bar for plates/faces.

- Distribution yard (night operations): thermal tripwires along fence lines; PTZ call-ups to verify tailgating; white-light deterrence only on verified events to avoid worker glare fatigue.

- Airport perimeter segment: thermal detects cross-line entries in zero light; radar overlay confirms trajectory before PTZ call-up. False alarms reduced where runway heat plumes were masked.

- Corrections facility: thermal on perimeter berm; PTZ presets target sally ports; alarms auto-bookmarked; maintenance cadence includes weekly lens cleaning and quarterly NUC checks.

- Wildlife conservation zone: thermal detects after-hours human presence; visible ID only at entry points to reduce data collection scope; LTE thumbnails + event clips; monthly ranger review.

- Construction laydown yard: thermal sweep with mobile mast; PTZ confirms brand/color; police evidence packs exported with VMS bookmarks.

- Search & rescue (UAV + vehicle mast): UAV thermal payload scans large areas; vehicle mast provides persistent overwatch; PTZ provides color ID when subjects located; all events bookmarked and synchronized post-mission.

Maintenance & Service Snapshot

- Germanium window care: durable but not glass—use manufacturer-approved cleaners; avoid abrasives/solvents.

- Sun/thermal load: prolonged direct solar heating can elevate noise or trigger protection; use sunshields, appropriate tilt.

- NUC shutter life: schedule scene-based NUC; excessive cycling shortens life and creates brief blind spots—log NUC cycles.

- De-icing & insects: mild ring heat and deterrent rings reduce icing/insect hits; keep a cleaning kit on-site.

- Seals/cables/grounds: seasonal checks; verify gaskets, strain relief, and bonding.

- Firmware/analytics policy: standardize versions; change-log updates; verify analytics after every update; keep 1–2 spares for rapid swap.

Buyer’s Guide (Deeper Procurement Detail)

1) Objectives & Ranges

- Define detection and recognition distances; specify ID method (visible/PTZ).

- Note privacy constraints, lighting policy, wildlife and neighbor considerations.

2) Sensors & Optics

- Resolution & pixel pitch: 320×240 (budget/short spans) vs 640×512 (cleaner silhouettes, longer spans). Smaller pitch (e.g., 12 μm) improves micro-detail in same form factor.

- NETD: target ≤50 mK where budget allows; lower NETD helps micro-contrast in fog/rain.

- Optics: germanium cost scales with focal length; motorized zoom eases commissioning but adds cost and potential export complexity.

3) Frame Rate & Export Class

- ≤9 Hz uncooled LWIR: broadly available and sufficient for most fence/approach detection.

- Higher frame rates/resolutions may require licensing and add cost/lead time—confirm early.

4) Analytics & Integrations

- Prefer object-based analytics (size/speed/direction) over raw motion.

- Confirm ONVIF events, PTZ preset mapping, VMS bookmarking, health/heartbeat telemetry, and ticketing/webhooks if needed.

5) Environment & Mechanics

- Verify wind-load, heater/defog, surge, and mount options; plan for salt/corrosion in coastal sites.

- Manage HVAC/exhaust FOV; consider shields and alternate angles to reduce hot-clutter.

6) Power & Backhaul

- Edge recording with thumbnail/clip sync over LTE/LEO; bulk retrieval via off-peak windows or PTP.

- Size solar/battery to winter PSH and multi-day storm recovery; include watchdog reboots and telemetry.

7) Serviceability & Lifecycle

- Labeling, access, NUC scheduling, spares, and a cleaning cadence.

- Document presets, alarm rules, and acceptance tests; train staff for seasonal adjustments.

Common pitfalls (avoid):

- Expecting thermal to deliver ID like visible at night.

- Mounting where hot industrial sources dominate the scene.

- Underspec’d optics for long ranges.

- Sizing solar by summer sun only; ignoring storm recovery.

- Skipping ROI/AGC tuning and misaligned PTZ boresight.

Key Terms (Glossary)

- Thermal IR (LWIR): long-wave infrared; sees heat patterns, not visible light.

- Uncooled vs Cooled: uncooled microbolometers (common/affordable) vs cryogenically cooled (high performance, costly).

- Pixel Pitch (μm): distance between pixels; smaller pitch often improves detail in the same package.

- NETD (mK): noise-equivalent temperature difference; lower = better micro-contrast sensitivity.

- AGC: auto gain control; maps scene temperatures into display range—keep stable for analytics.

- DDE: digital detail enhancement; adds edge pop—overuse can create artifacts.

- ROI: region of interest; weights AGC/analytics toward the critical zone (fence, waterline, corridor).

- NUC: non-uniformity correction (flat-field) to smooth sensor offsets; schedule wisely.

- Mixed-Modality: thermal + visible together; detect on thermal, verify/ID on visible/PTZ.

- PTZ Call-Up: automated preset move of a PTZ camera on an alarm (often via ONVIF/VMS).

- Johnson’s Criteria: rule-of-thumb pixels-on-target for detection/recognition/ID.

- IFOV / F-number / MTF (advanced): angular pixel size / lens speed / modulation transfer—optical factors that influence clarity.

FAQ

Can thermal replace lighting?

For detection, yes—thermal doesn’t need visible or IR light. For identification, pair with visible/PTZ (and lighting if needed).

Will fog or rain break thermal?

Thermal penetrates haze/fog better than visible, but heavy rain/fog reduces contrast. Keep NETD/AGC conservative; consider dual-tech confirms.

Are 9 Hz cameras too slow?

For fence lines and approaches, ≤9 Hz is typically adequate. If you need fast tracking at distance, consider higher-rate variants (check export rules).

How do I keep alarms effective but low?

Use object analytics, size/speed/direction filters, exclude static hot zones, and combine thermal detect + PTZ verify (or radar/PIR dual-tech).

Talk with an Engineer

Need help selecting focal length vs resolution, planning off-grid recovery, or integrating thermal with PTZ call-ups and edge-first retention? Contact A2Z for a tailored design.

- Discovery of objectives, ranges, backhaul, power envelope

- Sensor/lens shortlist (320×240 vs 640×512, pixel pitch, NETD) with pros/cons

- Draft layout + watts/bitrate envelope + winter PSH recovery check

- Integration notes for VMS workflows, deterrence, and health monitoring

Next Steps

- Learn analytics basics: All About Video Analytics & AI

- Compare camera roles: PTZ vs Fixed Cameras

- Compare options: Panoramic & Multi-Sensor vs PTZ (Solar Sites)

- Plan power/backhaul: Solar Camera Power Planning Guide · Security Camera Storage Options